FBE / EPOXY Coating Fitting, Flanges & Long Radius Pipe Bend

- Home

- Product

- FBE / EPOXY Coating Fitting, Flanges & Long Radius Pipe Bend

FBE Coated Pipe Fittings, Epoxy Coated Pipe Fittings, FBE Coated Flanges, Epoxy Coated Flanges, FBE Coated Long Radius Pipe Bend, Epoxy Coated Long Radius Pipe Bend, Fusion Bonded Epoxy Coated Fittings, Fusion Bonded Epoxy Coated Flanges, Fusion Bonded Epoxy Coated Pipe Bends, FBE Epoxy Coated Piping Components, FBE Epoxy Coated Industrial Fittings, FBE Epoxy Coated Pipeline Fittings, Epoxy Coated Pipeline Components

FBE / EPOXY Coating Fitting, Flanges & Long Radius Pipe Bend are manufactured to provide reliable corrosion protection for piping systems operating in aggressive and corrosive environments. Fusion Bonded Epoxy Coating, commonly referred to as FBE or Epoxy Coating, forms a tough, uniform, and chemically resistant layer over the steel surface, extending service life and reducing maintenance costs.

FBE / Epoxy Coating is widely used to protect pipe fittings, flanges, and long radius pipe bends used in oil & gas, petrochemical, power, water transmission, and industrial pipeline systems. The epoxy-coated components offer excellent resistance to moisture, chemicals, soil corrosion, and mechanical damage, thereby contributing to long-term pipeline integrity.

We offer FBE / Epoxy Coated Pipe Fittings, Flanges & Long Radius Pipe Bends manufactured in accordance with international standards. The coating is applied through an electrostatic process on properly surface-prepared components to ensure strong adhesion and uniform thickness.

FBE / Epoxy coated fittings, flanges, and bends are strongly recommended for underground, above-ground, and submerged pipeline installations, particularly in corrosive environments such as coastal regions, industrial zones, and chemically aggressive service conditions.

FBE / EPOXY Coating Fitting, Flanges & Long Radius Pipe Bend Specification

| Material Standards | ASTM, ASME, ISO |

| Coating Standard | ASTM A775 / A775M |

| Fittings Standard | ASME B16.9 / ASME B16.28 |

| Flange Standard | ASME B16.5 / ASME B16.47 |

| Pipe Bend Standard | ASME B16.49 |

| Coating Type | Single Layer FBE / Dual FBE |

| Size Range | As per project requirement |

| Thickness | As specified in coating specification |

The advantage of using factory-applied FBE / Epoxy coating on fittings, flanges, and pipe bends lies in consistent coating quality, controlled thickness, superior adhesion, and reduced on-site coating requirements. Machine-controlled coating application ensures uniform coverage even on complex geometries such as long radius bends and fitting contours.

Let’s discuss about your ongoing project

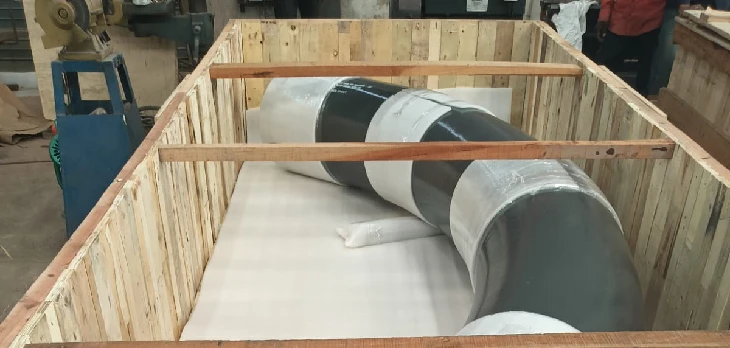

FBE / EPOXY Coating Fitting, Flanges & Long Radius Pipe Bend Packaging

FBE / EPOXY Coating Fitting, Flanges & Long Radius Pipe Bend are widely used in industries including oil and gas, petrochemical, power generation, chemical processing, water treatment, pulp and paper, and bulk fluid transportation. All products are manufactured and coated in accordance with international quality standards.

FBE / Epoxy Coated fittings, flanges, and pipe bends are packaged to ensure there is no damage during transit. For export orders, standard export packaging is provided in wooden cases. Each product is marked with Grade, Lot Number, Size, Bend Degree (where applicable), and manufacturer’s identification. Custom marking and special packaging can be arranged upon request.